Message from the Owner

Toward More Joy & Less Pain During LambingShed lambing 200 ewes at Premier began 16 days ago. How did it go? Better than any prior year. Weather for the first 7 days was unusually mild. Last 9 days was colder and often windy. On several nights it was cold enough inside our barns to freeze a newborn's navel cord within an hour. 90% have lambed. 15 triplets, 25 singles, 140 twins. No midgets. No prolapses. 1 non-systemic abortion. No major dystocia events. No hypothermia. No e coli. No pneumonia. 2 ewes with mastitis. 2 ewe deaths. 12 lamb deaths (out of 350 lambs) from various causes. Why did it go as well as it did?

So why am I far from satisfied with Premier's lambing system?

But raising sheep, goats or cattle should, in my mind, offer as much pleasure and as little pain as possible. We're not "there" yet. Our options? Unlike the range operations of the West we can't spread 200 ewes over 1000 acres and let them "do their own thing". And our expensive land necessitates a high lambing %. But we could:

by Stan Potratz Special Price from Premier!

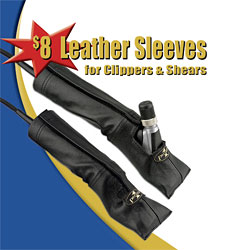

Premier's Clipper & Shear SleevesOrder Premier's leather clipper machine sleeve (#824608) and/or shear machine sleeve (#824607) in April and May for $8 ea. (reg. $9.75 ea.) Genuine leather sleeves to care for and enclose your Premier shears and clippers. Protects entire machine (not just the head) when not in use. Great for those that place multiple units in a show box or tool box. Designed for Premier units, may not work with other brands. To Order: Website: - Use Code News 24IT Offer good through May 31, 2007. Premier VIP

Getting More from Your Pasture AcresThe bioeconomy may be great for corn producers but it is putting a squeeze on sheep and goat producers. Competition for all land has and probably will continue to escalate as corn prices hover in the $3.50 to $4.00 range. The high corn prices will indirectly increase both hay and pasture costs for us as producers. Everyone is looking for a cheap replacement feed to corn. Existing pasture is the cheap feed alternative with ewe costs per day running 10 - 30% of dry lot costs on a per day basis. The first and most effective means of getting more from our pastures is with improved fertility. Pasture yield can be increased by one half to one ton per acre with 50 units of nitrogen. Current costs for nitrogen is in the mid forty cent range. If one includes spreading costs the total cost for a single 50-unit application is approximately $25 per acre. If one grows one half ton of extra grass, the cost is $50 per ton for the extra feed. That is cheap feed compared to corn at $125 per ton or hay at $100 per ton. If you time the application right and get great rain distribution, you could be getting extra grass at $25 per ton if yield is increased by a ton per acre. Fertility cost has a great return on the cost with increased forage yield. Every day one grazes versus feeds a ewe harvested feedstuffs, it is a savings to your operation. If you already have excess spring growth that the ewes can not consume or you can not hay, than delaying nitrogen application to mid-June makes more sense. If one really wants to push the forage yield than a second and possibly third application of nitrogen should be considered. These applications should be made in mid June and early August in the Midwest. Producers in southern states should contact their forage specialist to seek advice on when to apply nitrogen. Early turnout is another management blunder that reduces the overall productivity of pastures. Bluegrass pastures should be two inches tall and actively growing before turnout. Brome grass or orchard grass pastures should be four inches tall before turn out. No one likes buying hay in late spring if the winter supply is fed up, but early turn out is not a good trade. The reduced yields may require more supplementation in the summer that increases the feed costs. The old adage of pay me now or pay me later applies here. Developing a more realistic winter feed budget and insuring one does not run out is a step that needs to be taken for future years so early turn out is not so tempting. Carry over hay is a good thing and all operations need to plan for 10 to 20 percent carryover. Rotational grazing is another means of generating increased production per acre. Estimates range from 20 to 100 percent increase in production with moderate to intensive rotational systems. Many producers immediately respond that they can not rotationally graze. I say they choose to let their flimsy excuses prevent them from trying. Yes some pastures are not ideal for subdividing but think creatively. For example cross fencing creek pastures may require more time for upkeep after heavy rains. Sheep do not like water any way so until the creek goes back down they are not going anywhere. In many cases splitting the pasture up into 2 or 3 areas can have a dramatic impact on yield. One does not have to put in super intensive systems with daily rotations for the concept of rotational grazing to work. First year improvement in yield should be a 10 - 20% increase followed by 10 - 20% increase in years two and three. This delayed yield response is from sward thickening and increased composition of tall cool season grasses which are allowed to achieve a high percentage of its yield potential. How many paddocks one subdivides a pasture into is really dependent on ones time available for moving stock and tending fences. My recommendation is to start with 3 - 6 paddocks and increase at a later date if great grazing becomes a passion. ("No Stan is not paying me to say this.") Many producers are looking for the silver bullet forage species. The one that does not need management, has great yields, is easy to establish, and sheep love it. Unfortunately, the silver bullet does not exist for forage species. Secondly, until one has a better handle on fertility and grazing management incorporating improved forage species is a waste of time and money. Incorporating legumes via frostseeding or no till drill can greatly improve the nutritive value of forage. Additionally, adding legumes helps reduce the summer slurp. Poorly managed pasture with weed and thistles problems should be cleaned up prior to considering legume incorporation. Improved species mixes I feel is the last step to improve pasture production. Fertility and rotational grazing will both greatly increase production. Delayed spring turnout along with minimizing overgrazing in the fall will also allow pastures to grow more grass. Grazing management has an initial cost whereas yearly harvested feeds has a cost every year. Pasture management is one step towards battling high feed costs that all producers can implement. Article submitted by: Dan Morrical, Sheep Extension Specialist Premier TipRotational GrazingWorking away from home and still wanting to practice rotational grazing requires having the right equipment on hand. Especially if you want your underpaid spouses and kids to move the fence for you during the day. Any time we can split a paddock for sheep with five rolls or less we use ElectroNet. The whole fence can be carried out to the paddock in one trip. It can be set up quickly with out the need of any tools. The posts are built in so there is no questions on how far apart they should be and easy for any size person to get the right tension on the fence. Sometimes you will find that the grass is tall enough that it is hard to set the net up and push in the posts. A simple solution to this is to drive your ATV, truck, or even a garden tractor down the path where you want the fence to be. Then set the net upin one of the tire tracks. Two or three Power posts for extra support at the corners, a PowerLink to connect to a hot wire. Test the fence with a fence tester and make sure the voltage is above 3000 volts and turn in the sheep. See Premier's full line of electric netting. by Sales Consultant, Gordon Shelangoski Premier Employee Spotlight

Mark EmbreeOperations Manager After being here six years, Mark says "the best part about Premier is still the commitment to customer satisfaction through great customer service and products." The best part about my position, Mark says "is the owners as well as the staff make Premier a great work environment for me. We work very hard to succeed and have a lot of fun along the way." Mark and his wife Toni, who is Premier's receptionist, have been married for 20 years, have two sons - Cody, 15 and Cole, 9. He owns a German Shorthair hunting dog named Buck, and he says, "I think we have a cat." Besides all hunting, fishing and sports activities, Mark enjoys activities with his family and especially barbecuing. He is known far and wide for his culinary skills. His favorite statement is "motivation will almost always beat mere talent. Motivation is what gets you started. Habit is what keeps you going." Mark is a driving force at Premier, his abilities, energy and enthusiasm continually help move Premier forward. RecipeRoast Beef with Horseradish SauceIngredients: Preheat oven to 325 degrees. Combine first four ingredients in a bowl and refrigerate. Season roast with salt and pepper to taste. Heat oil in a heavy flameproof casserole over medium high heat. Saute roast 2 - 3 minutes until brown on all sides. Transfer to oven and roast 22 minutes per 1 lb. for medium rare meat. Cook longer if desired. Let stand 15 minutes before cutting into thin slices and serving with horseradish sauce. |