Wood Line Post Insulators

Product Details

For attaching low-tension conductors to wood line posts. Premier alternative to the common ring insulator. Wider, deeper threads stay in wood posts better.

For easy installation, use a Wood Post Line Power Driver.

Common Uses

Specs

- Made of polyethylene with UV additive for extra long life

- Spike: 1-1/2" long (3/4" is threaded)

- 25 per package, but sold individually

Installation

- Predrill hole into wood post

- Put bit end of Wood Line Power Driver into chuck of drill and tighten

- Place power driver over the insulator line up with pin inside cup of driver

- Insert the screw tip of insulator into the predrilled hole

- Thread conductor through insulator

- Pre-drill hole into wood post

- Screw insulator completely into the post

- Thread conductor through insulator

Tips

In very hard posts, a 3/16" predrilled hole is required.

Listed below are recommended optional components or related items. Your particular situation may require alternative recommendations. Please call and talk to our consultants if there are any questions at 800-282-6631.

-

Insulators

Wood Line Power Driver

Item #380710 -Install wood-line post insulators quickly and efficiently by attaching a Power Driver to a battery powered screw gun.

$9.50 -

Conductors - Rope-Twine-Wire-Tape

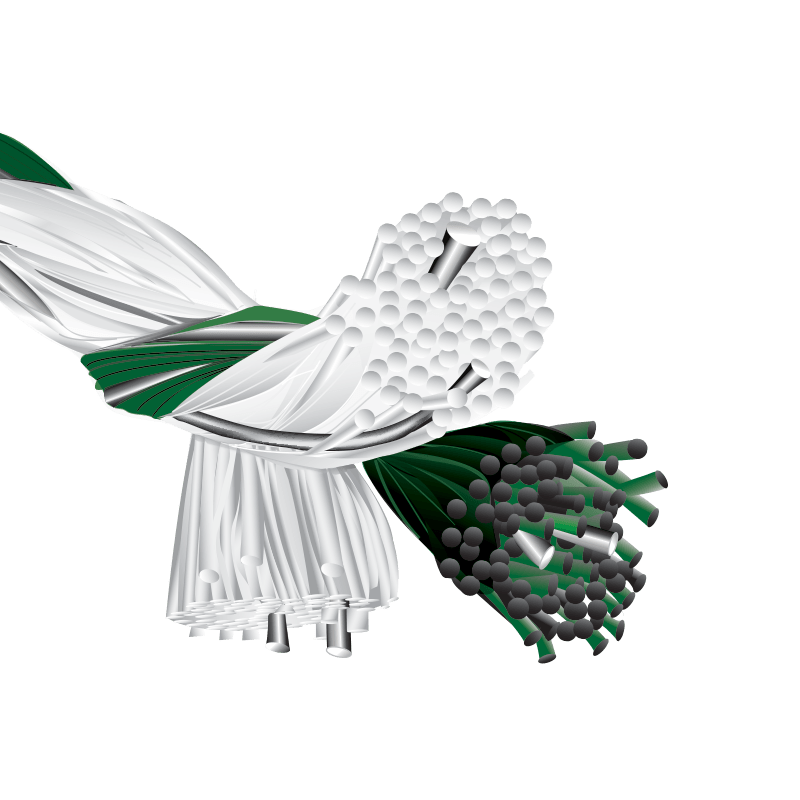

IntelliBraid®, 660 ft. roll

Item #256710 -6mm (1/4") dia. braided rope conductor for electric fences. Black/white color is easy for humans and livestock to see. Polyester for high UV-resistance.

$113.00 -

Conductors - Rope-Twine-Wire-Tape

IntelliBraid® Grazer 2.6, 2000 ft roll

Item #253537 -Premier’s most conductive low-tension electric fence twine—only 20Ω per 1,000 feet! 2.6mm diameter for portability and ease of handling. Ideal for sheep and cattle.

$90.00 -

Conductors - Rope-Twine-Wire-Tape

EnduraSoft® 6.0, 660 ft roll

Item #256500 -Highly visible polyester electric fence conductor with excellent conductivity over long distances. 6mm (1/4") diameter. 25 years probable life.

$98.00 -

Conductors - Rope-Twine-Wire-Tape

IntelliRope® PE 6.0, 660 ft. roll

Item #256900 -6mm (1/4") dia. electrifiable rope for permanent or temporary fences. Polyethylene filaments resist wear and abrasion. An effective anti-deer conductor.

$59.00 -

Conductors - Rope-Twine-Wire-Tape

IntelliRope® PE 4.5, 660 ft roll

Item #245100 -4.5mm (3/16") electrifiable rope for permanent or rotational grazing fences. Tinned copper filaments for high conductivity (50 Ω per 1000 ft).

$40.00 -

Conductors - Rope-Twine-Wire-Tape

IntelliBraid® Twine PE 3.0, 660 ft roll

Item #253530 -Lightweight 3mm braided polywire for portable livestock fences. Slightly thicker than standard twine so it’s more visible to animals and humans.

$28.00 -

Conductors - Rope-Twine-Wire-Tape

IntelliTwine™ 2.25, 660 ft. roll

Item #253500 -2.25mm (12 gauge/.09" dia.) electric fence conductor for temporary livestock and garden fences. Lightweight and easy to move.

$23.00 -

Conductors - Rope-Twine-Wire-Tape

MaxiShock™ Wire, 1320 ft. roll

Item #251000 -Twisted cable conductor for electric fences. Thick layer of galvanized coating for years of outdoor use.

$129.00 -

Fence Connectors and Accessories

Conductor Hook

Item #237400 -A quick, easy way to terminate a fence. Secures and insulates the leading end of twine, rope or tape to an existing fence.

$1.25 -

Fence Connectors and Accessories

PowerLink™ 4.0, 48" long

Item #335505 -Make instant, in-field connections between electric fences without turning off the energizer. Simple to use and effective.

$5.50 -

Fence Connectors and Accessories

Fence & Battery Digital Tester

Item #200010 -All-in-one fence tester checks the voltage of energizers, fences and 12V batteries. Simplify electric fence troubleshooting with one device!

$38.00 -

Fencing

Warning Sign

Item #346000 -Let passersby know that your fences are electrified with this easy-to-read electric fence warning sign.

$2.50

Write a Review

You must be logged in to leave a review. Please sign in.

Audrey M from Tennessee

I love these. At first I was perplexed as to how to remove, you can use a screwdriver to screw them in but that doesn't work in reverse. However, what DOES work for both installation and removal is a chainsaw socket tool (about $7). Also called a scrench. The socket end of that tool lets you use it as a fulcrum. Love these insulators!!!

Pamela S

Easy peasy to install. Can't attest to wear as we just put them up.

Marcia R from Maine

Needs to be a little stronger

Leon E from Florida

The worst product I've ever got from Premier (and in 8 years or so I only had 2 Premier products that I was less than completly satisfyed with). Unlike similar product from a competitor these are pain in the neck to install (even with the special tool) because they need predrilling, disengaging the tool is more difficult, you never know which way the openning faces, etc. All in all - about 50% more time per insulator than the competitor's product, which is also cheaper and makes much better terminal insulators for low-tensile.

Susan S from Prince Edward Island

Great product for the price, only downside for me is that they are difficult to remove.